- Register

- Log in

- Wishlist (0)

- Cart (0) You have no items in your shopping cart.

Quotes Available

Blog

A well-functioning car air conditioning system is a lifesaver during those scorching summer days, but have you ever wondered how this cooling miracle occurs? Original Air takes you on a journey, providing a detailed analysis of how the air conditioning system works, with a specific focus on the essential role of refrigerant in your vehicle's cooling system.

Car AC 101: Understanding the Role of Refrigerant in Your Vehicle's Cooling System

At the core of any vehicle's air conditioning system lies a special substance known as the refrigerant. This chemical compound plays the indispensable role of absorbing heat from the vehicle's cabin and expelling it outside, thus keeping the interior cool and comfortable.

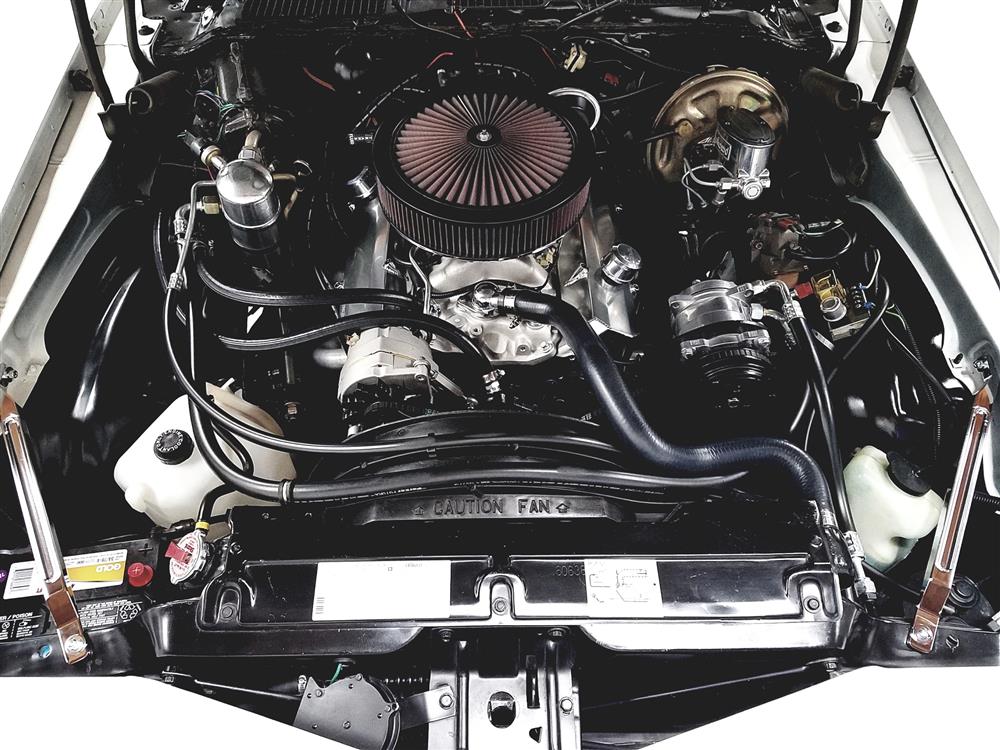

Understanding the air conditioning system in your vehicle requires a look into its internal mechanics. The system comprises various components, including the compressor, condenser, expansion valve, and evaporator, with refrigerant being the fluid that flows through these parts. Each component plays a crucial role in the cooling process.

The Role of the Compressor - The compressor, often referred to as the heart of the air conditioning system, is responsible for pumping refrigerant through the system. It compresses the refrigerant, raising its pressure and temperature, and pushes it towards the condenser.

The Condenser's Function - The condenser's function is akin to a radiator, and it's usually located near the front grill of your vehicle, allowing it to cool off with the incoming air. As the hot refrigerant from the compressor enters the condenser, it releases its heat to the cooler ambient air, condensing into a high-pressure liquid.

The Role of the Expansion Valve - Next in line is the expansion valve, which acts as a restrictor, rapidly decreasing the pressure on the refrigerant, causing it to cool significantly. It's at this stage that the refrigerant turns into a low-pressure, cold liquid-vapor mix.

The Evaporator and its Significance - The cold refrigerant then proceeds to the evaporator, located inside the cabin. As the cabin air blows over the evaporator's cold surface, the refrigerant absorbs the heat, cooling the air. The refrigerant then goes back to the compressor, and the cycle repeats.

Different Types of Refrigerants and Their Evolution

There are various types of refrigerants, and their use has evolved over the years due to environmental concerns and technological advancements.

R-12 Refrigerant

R-12, commonly known as Freon, was the first mainstream refrigerant. However, it was discovered that R-12 was harmful to the ozone layer, leading to its phase-out in the 1990s.

R-134a Refrigerant

R-134a replaced R-12 and is still widely used today. It is much safer for the environment, but it's not as efficient as R-12, leading to the search for more efficient refrigerants.

R-1234yf Refrigerant

R-1234yf is the latest refrigerant on the market. It offers superior cooling capabilities and has a much lower environmental impact than its predecessors. However, it's more expensive, causing some manufacturers to hesitate in adopting it.

The Importance of Proper Refrigerant Levels

Having the correct amount of refrigerant is essential for your car AC's optimal performance. If the levels are too low, the AC system will not cool effectively. On the other hand, an overcharged system can lead to component damage.

Checking and Recharging the Refrigerant

If your AC isn't cooling as effectively as it should, the refrigerant might be low. Most auto parts stores sell recharging kits that can replenish the refrigerant. However, if you're unfamiliar with the process, it's best to consult a professional.

The Environmental Impact of Refrigerants

While refrigerants make our rides comfortable, they can have significant environmental impacts if not properly managed. Leaks can release these substances into the atmosphere, contributing to global warming. Therefore, ensuring your AC system is leak-free is not only important for your comfort but also for the environment.

FAQs

What role does refrigerant play in a car's AC system?

The refrigerant in a car's AC system absorbs heat from the cabin and expels it outside, thus cooling the interior of the vehicle.

What are the key components of a car's AC system?

The key components of a car's AC system are the compressor, condenser, expansion valve, evaporator, and refrigerant. At Original Air, we keep these components in stock for classic cars from the 60s to early 90s.

What are the different types of refrigerants?

There are several types of refrigerants, including R-12 (Freon), R-134a, and R-1234yf, with each having its advantages and disadvantages.

How often should the refrigerant be checked or replaced?

While there isn't a fixed schedule for checking or replacing the refrigerant, it's recommended to do so whenever you feel your AC isn't cooling effectively.

How does refrigerant impact the environment?

Refrigerants can contribute to global warming if they leak into the atmosphere. Therefore, maintaining a leak-free AC system is crucial for environmental preservation.

Can I recharge the refrigerant myself?

Yes, you can recharge the refrigerant yourself using a recharging kit. However, if you're not comfortable doing so, it's recommended to consult a professional.

Understanding the role of refrigerant in your car's AC system is key to ensuring a comfortable ride, particularly during hot weather. Proper maintenance of the refrigerant level not only ensures optimal performance but also minimizes environmental impact. When in doubt, giving Original Air a call can prevent potential damage and ensure your vehicle's AC system stays in top condition.

Carroll Shelby kick-started a thrilling partnership with Hertz in 1966, when he successfully persuaded the company to order 1,001 Ford Mustangs, finely tweaked by his garage. This laid the foundation for the iconic "Rent-A-Racer" program, which marked the birth of the Shelby G.T.350H. Almost instantaneously, these machines began leaving tire marks on race tracks and dragstrips alike, rapidly expanding the program's legend. After a 40-year hiatus, Hertz rekindled the project, rolling out yet another Shelby Mustang but with stricter terms in the rental agreement. Ever since, the Hertz special editions have been a constant presence in the car world, each model featuring unique tweaks and available in restricted quantities, with the most recent being the 2020 Hertz-Hendrick Motorsports Camaros. Buckle up as we give you a spin through the journey of these speed beasts, all of which donned the distinctive black and yellow livery, plus a special guest.

1966 Ford Shelby G.T. 350H

This trailblazer, infamous for its high-performance in its time, was notorious for tales of renters striping it for parts. Powered by the K-code 289 V-8 engine that was finely tuned in Shelby's Venice, California shop to a roaring 306 horsepower, these rides were virtually identical to the standard G.T. 350 save for the rear side glass. Noteworthy is the elevated price tag, which has rocketed from a humble $17 daily rental fee to a six-figure sum, should you find one of the original 1,001 units.

1985 Ford Mustang SVO

Though not originally a Hertz special, the SVO, an exclusive Mustang edition with a turbocharged four-cylinder, made it to Hertz's "Rent-A-Racer" program in 1985. Interestingly, all 60 copies bought by the rental company had manual transmission, a feature rarely seen in the other cars in this list. The distinct Dark Sage green paint, commissioned by Hertz, adorned ten of these vehicles, making them stand out among the 47 cars that featured this color.

2006 40th Anniversary Ford Shelby GT-H

The flame between Carroll Shelby and Ford was reignited in 2003, leading to the launch of a new Mustang in 2005. A year later, the Shelby name graced the Ford showrooms again, right on time for the 40th anniversary. Sporting parts from the Ford Performance catalog, the GT-H, both standard and rental versions, came with enhancements like a cold air intake, engine tune, and more. A total of 496 GT-H units were built, with only Carroll Shelby and Hertz executives privileged enough to get one with a manual transmission.

2007 Shelby GT-H Convertible

As expected, the GT-H Convertible followed the coupe, sporting similar upgrades and also limited to 500 copies. The initial 2006 prototype model was auctioned in 2012 for a hefty $115,500.

2008 Chevrolet Corvette ZHZ

In 2008, General Motors jumped on the Hertz special bandwagon with the Corvette ZHZ. This model was a part of Hertz's "Fun Club" line of sporty rentals and started with an initial run of 500. The ZHZ boasted an identical 436 horsepower from the LS3 V-8, just like the stock Corvette, but carried special Hertz touches inside and out.

2009 Chevrolet Corvette ZHZ Convertible

The pattern of following a coupe with a convertible continues here as well, with a limited 375 units run, making it one of the most exclusive Corvettes ever made.

2014 Hertz Penske GT

In this iteration, Hertz collaborated with Penske Racing, resulting in the birth of the Hertz Penske GT. The upgraded parts largely came from the Ford Performance catalog, including a new exhaust, air intake, ECU tuning, and more. This special edition maintained the tradition of offering automatic transmission to the rental fleet, with just 10 manual versions going to executives and VIPs.

2016 Ford Shelby Mustang GT-H

To commemorate the 50th anniversary of the original "Rent-A-Racer", Hertz and Ford collaborated once more to release another 140 GT-H units. This beast was based on the stock Mustang GT and featured a Ford Performance exhaust along with the Ford Racing Handling Pack.

2018 Hertz 100th Anniversary Edition Chevrolet Corvette Z06

Hertz celebrated its centennial with this special edition. The Z06 was mostly a stock model, but with an impressive 650 horsepower and 650 pound-feet of torque paired to an automatic transmission. Only 100 units were manufactured, making this 2018 model rarer than the Corvette 65th-anniversary Carbon 65 Edition cars.

2020 Hertz-Hendrick Motorsports Chevrolet Camaro ZL1 and SS

Hertz's association with Hendrick Motorsports led to the creation of this pair of Camaros. The Camaro SS features a cold air intake and an exhaust, increasing the output to 480 hp. Meanwhile, the ZL1, limited to just 24 units, came with a bigger supercharger on the LT4 V-8, delivering an impressive 750 hp and an 11.0-second quarter-mile time.

2022 Ford Shelby Mustang GT-H

The latest addition to the line of Hertz special edition cars is the 2022 Shelby Mustang GT-H, which stands out with its unique styling upgrades that honor a rich performance heritage. The Shelby GT-H, available as fastbacks and convertibles, comes in four exterior paint colors: rapid red metallic, oxford white, carbonized gray, and shadow black. All models sport gold “Le Mans” dual racing stripes and special rocker stripes, along with Hertz Edition and Shelby 60th anniversary emblems for a distinctive look.

The interiors are adorned with Shelby and Hertz logos on the seats, sill plates, and floor mats, while a numbered badge is located on the dashboard and under the hood. Performance-wise, the Shelby GT-H features a Borla cat-back performance exhaust for the 5.0L V8 engine and a staggered wheel kit for both convertibles and fastbacks. The GT-H rides on 20-inch aluminum wheels with all-weather Michelin tires and sports a unique Shelby-designed deep-draw hood, upper grille, fascia winglets, and taillight panel.

- 2023

- 2022

- 2021

- 2020

- 2019

- 2018

- 2017

- 2016